Why needed EMI shielding

Electromagnetic interference (EMI) is any electromagnetically induced transmission that can adversely affect the performance of an electronic device. There are many devices that can generate EMI including motors, power supplies and digital electronics.

In electronic packages, the design of the flexible circuit or printed circuit board is a critical consideration in mitigating the effects of EMI since the changing current produced by active devices are propagated across the conductive traces of the circuit. For this reason the flexible circuit will often need to incorporate some sort of EMI shielding.

Electromagnetic shielding film

Electromagnetic shielding film Also called EMI protection film, or absorbing material which mainly used to weaken or eliminate the effect of electromagnetic interference for the internal wiring, through cutting process and pressing on the free-adhesives FCCL or on covering membrane.

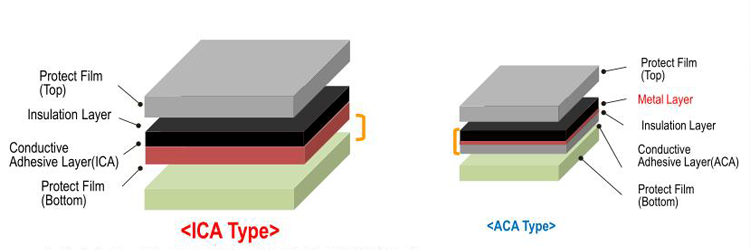

Selective openings in the coverlay film allow the conductive adhesive to electrically contact the flex circuit. This creates a shielding layer by the contact between the metalized film and the ground traces.

EMI is applied in consumer electronics (such as mobile phone, tablet PC, touch panel, digital camera, LCD TV and etc.).

Frequently-used EMI shielding Film model

| Brand | Part Number | Thickness |

TATSUTA | SF-PC5000/5500/5900 | 22um/22um/10um |

TATSUTA | SF-PC1000 | 32.1um |

TOYOCHEM | TSS200/TSS100 | 22um/12um |

Other Common EMI Shielding Way

Solid Copper is the most common method of shielding. Solid copper shields increase the rigidity of the circuit, and should be included in thickness to bend radius ratios. Copper shields can be put on one or both sides of the circuit. Solid copper can also cover selective conductors.

Crosshatching is an artwork design that relieves much of the copper shield areas by the use of a pattern. Crosshatching helps the circuit to improve its flexibility and can be put on one or both sides. Crosshatch shielding can also cover selective conductors.

Conductive silver can be screen printed onto the surface of a flexcircuit as a substitute for the copper shielding in some applications. Openings in the coverlay dielectric allow grounding contacts. Silver shielding is not recommended for a dynamic flexing application as it is more brittle and has poorer adhesion characteristics vs. other alternatives. As such, it may be prone to cracking in severe bending applications. Silver can be a solid or crosshatched shield and can be put on one or both sides of the circuit.