The bare copper on the PCB would oxidize and compromise the components soldering. As one of the last working steps in the PCB manufacturing, the bare copper on the PCB is coated with a surface finish.

The surface finish protects the underlying copper against oxidation and therefore increases storability. In addition, the surface finish is responsible for raising the wetting ability of the contact areas for soldering.

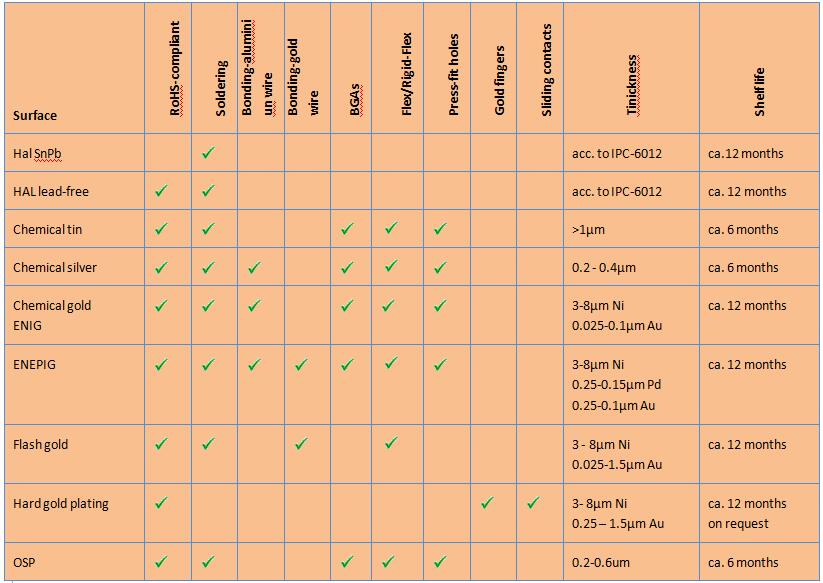

* IPC-6012: Fully covered and solderable

* For more information about Wire Bonding please click the link below: Surface Finish for Chip on Board Assembly

HASL is hot air solder leveling. It coated with molten tin(Pb) solder and heating the entire compressed air(blowing) level technology to form a layer of anti-oxidation of copper,but also provide good solderability coating.The HASL usually sinking in molten solder,air knife blow the solder liquid level before solidification.air knife can make solder copper to crescent-shaped with minimized and to prevent solder bridging. HASL-LF is HASL lead free.

Process capability: 2-40um

Immersion gold surface is wrapped with heavy nickel electrical gold alloy,which can be long-term protection PCB. In addition it has great patience for the environment that other surface treatment processes do not have . Immersion Gold can also prevent dissolution of copper,which will benefit the lead-free assembly.

Process capability:Au0.025-0.1um Nie:3-8um

OSP(Organic Solderability Preservatives) is a process of PCB surface-treated copper foil ROHS compliance requirements.It is grown an organic film layer with chemical methods in the clean bare copper surface.This membrane has oxidation resistance,thermal resistance and moisture resistance to protect the copper surface does not rust in the normal environment.It be required rapid clearance to flux in the subsequent high temperature solder.So the clean exposed copper surface can be combined with the molten solder joints immediately became solid in a very short period of time.

Process capability:0.2-0.6um

Since all current solders are tin-based, the tin layer can be matched with any type of solder materials. Immersion Tin process can formed planar copper-tin intermetallic compound, this feature makes immersion tin having a good solderability like HASL but without flatness problem. Immersion Tin board can not be stored for too long,Assembly must be followed the time of Immersion Tin.

Process capability:>=1um

Immersion Silver is between organic coating and Immersion Gold, the process is relatively simple and fast.the silver is till able to maintain good solderability even exposed to heat, humidity and pollution environment.Immersion Silver does not have good physical strength possessed like Immersion gold because there no nickel under silver layer.

Process capability:0.2-0.4um

ENEPIG(Electroless nickel electroless palladium Immersion Gold) is more palladium layer compared with Immersion Gold. Palladium appears to prevent corrosion caused by substitution reaction. It well prepared for Immersion Gold.Gold is closely covering the palladium,provide a good connection surface.

Process capability:Au:0.025-0.1um Ni:3-8um Pd:0.025-0.15um

Electro gold flash plating consists of a thin layer of gold over electroless or electrolytic nickel. This type of plating is hard and durable. It also has a long shelf life, lasting for years. However, its durability and shelf life make it more expensive than any of the finishes mentioned above.

Process capability:Au:0.025-1.5um Ni:3-8um

In order to improve the wear resistance of products,increase the number of plug of gold finger, hard gold plating surface is necessary.

Process capability:Au:0.25-1.5um Ni:3-8um