You could choose single piece to delivery. Or you choose “Panel by KingCredie”: boards be made panel format by our factory. Or you choose “Panel by Customer” :customer supplied panel format and requirements.

Please input the maximum width and length of your PCB design.

The number of boards/panels required. Note! If you choose "Panel by Customer", then this is the number of panels.

Choose the type of board, Flex or Rigid-flex boards.

The number of conductive layers.

The adhesiveless polyimide has longer bending life than the conventional polyimide. But its disadvantage is too expensive cost. If you not need bend the board frequently, we suggest the conventional polyimide, and choosing the material by the factory.

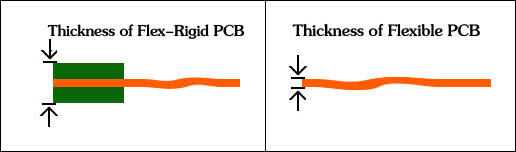

The finished PCB thickness.

Tips: The thickness here does not include the stiffener thickness of the flex part.

Tips: That we may charge additional fees if there is a specified lamination structure.

Tips: If it is a flex-rigid PCB, the thickness here refer to the total thickness of rigid pcb part.

Finished outer layer copper weight after copper plating.

Minimum trace width and spacing between copper features. Whichever is least. The copper thickness you select will determine how narrow a trace or space can be manufactured.

Coverlay color of flex part.

Silkscreen Color.

White

White Black

Black Yellow

Yellow Red

Red None

NoneExtra process to exposed copper to help solderability.

● ENIG(Immersion Gold): Gold:1-3 microinches, Nickel: >=100 microinches

● Immersion Silver: 6-15 microinches

● Immersion Tin: 30-47 microinches

● OSP(Organic Surface Protectant): 4-12microinches

● Bare Copper: No plating finishes

Outline shape of single board.

Rectangle

Rectangle Square

Square Circular

Circular Irregular Outline

Irregular OutlineIt is the material that used to increase FPC hardness.

Tips: The thickness here include the total thickness of flexible pcb and stiffener.

If it is flying probe test, we will charge the testing cost again when you repeat to order this board. If it is fixture test, we just charge the testing cost one time. When you repeat to order this board, we will not charge the testing cost again.

Fill in any details to make it as clear as possible for us to understand your requirements.

| Quantity | Build Time | Total |

| days | $ | |

| days | $ | |

| days | $ | |

| days | $ | |

| days | $ |

Quantity:

Build Time: days

Total:$

Tip:Not include shipping cost