RO4000® Laminates

Industry leading RO4000® hydrocarbon ceramic laminates and prepregs offer superior high frequency performance and low cost circuit fabrication resulting in a low loss material which can be fabricated using standard epoxy/glass (FR-4) processes.

RO4000 material possesses the properties needed by designers of RF microwave circuits and matching networks and controlled impedance transmission lines. RO4000 series laminates offer a range of dielectric constants (2.55 - 6.15), are available with UL 94 V-0 flame retardant versions.

Benefits

· Optimized cost and RF / microwave performance

· Compatible with FR-4 fabrication including multilayer PCB constructions

· High thermal conductivity for improved thermal management over traditional PTFE materials

· Robust lead-free solder processing compatibility

· Low Z-axis CTE for reliable plated through-hole quality

Typical Applications

· Cellular Base Station Antennas and Power Amplifiers

· Microwave point to point (P2P) links,Automotive Radar and Sensors

· RF Identification (RFID) Tags,LNB’s for Direct Broadcast Satellites

· Proprietary technology that allows reverse treated foil to bond to standard RO4000 delectric

· Significantly improves insertion loss and passive intermodulation (PIM) performance

· Lowest dielectric loss of the RO4000® product family

· The original RO4000 material used for over a decade in cost sensitive Microwave/RF designs

· Dk 3.38 (+/- 0.05); Df 0.0027@10GHz

· The market leading material for base station power amplifier designs

· Low loss, FR-4 processable and UL 94V-0 rated material

· Dk 3.48 (+/- 0.05); Df 0.0037@10GHz

· Based on RO4000 platform for low Dissipation Factor (.004 @ 10 GHz) and consistent Dielectric Constant (Dk)

· Fully compatible with FR-4 materials for complex hybrid multilayer designs

· UL 94-V0 rated

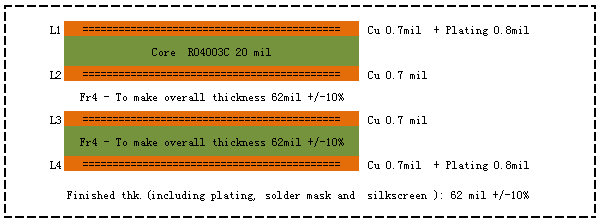

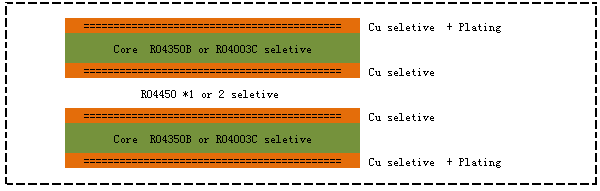

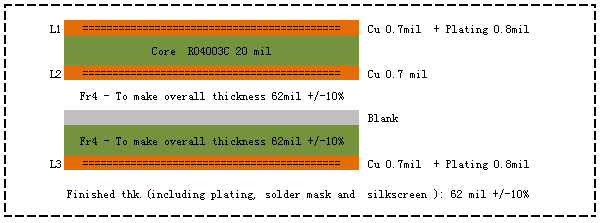

Rogers PCB 2L stack up

Example 1

Example 2

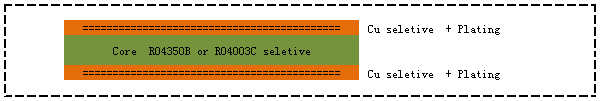

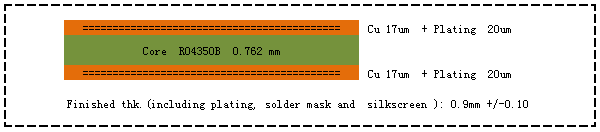

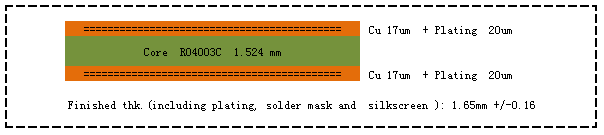

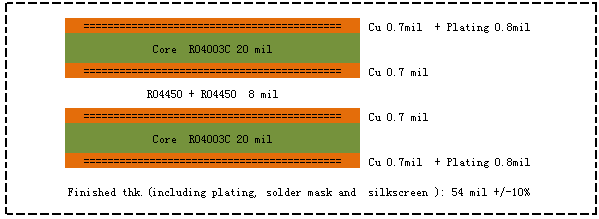

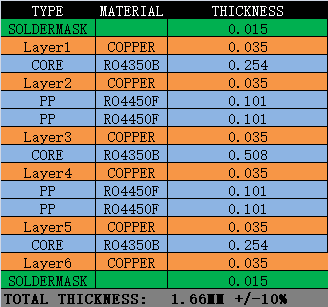

Rogers PCB Multilayer PCB stack up

Type A: Lamination structure fully using Rogers material

Note:You can use Rogers material in all layers, but normally we need to use core on the outermost layers because Rogers prepreg has insufficient bonding strength with copper foil. Using core on the outer layers prevents poor copper adhesion on the board's surface. Additionally, since signal lines are typically designed on the outer layers, using core there also ensures signal transmission quality.

Example 1

Example 2

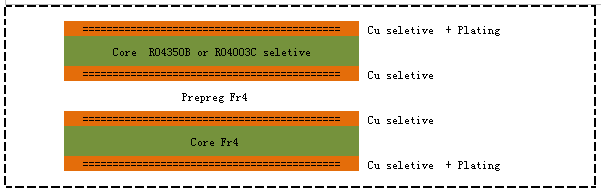

Type B: Mixed Dielectric (Hybrid stack-up)

Mixed high frequency construction can reduce costs when the need for RF dielectric is local and only between some layers. The rest of the dielectric can be FR4 or halogen-free FR4.

Note: Between Rogers and standard FR4 materials, only standard FR4 prepreg can be used, as Rogers prepreg has insufficient bonding strength with FR4 material. Using Rogers prepreg between different materials may cause delamination.

Example 1

Example 2