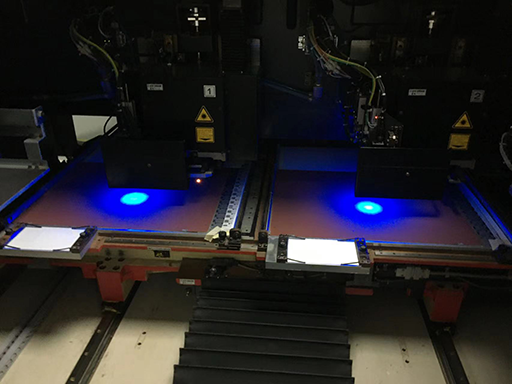

When using HDI technology for PCB designing, plenty of microvias are included. These microvias that appear to be blind structures are small in size and require precise controlled depth drilling. This precision can only be achieved using lasers.

Why mechanical drilling cannot be used for microvias?

1. It cannot achieve the precisely controlled depth drilling required for microvias.

2. It cannot drill holes with less than 4 mil diameter (approximately).

3. Mechanical drilling is accompanied by drill vibration.

Consideration for PCB Laser Drilling

1.Non-homogeneity of the stack-up

It is important to remember that different materials tend to absorb energies at different rates. It is, therefore, important that the PCB stack-up is kept homogenous as far as possible. With PCB materials that have varying optical and thermal properties, the reaction of the laser beams is also different. In turn, this leads to inaccurate drilling.

2.The thickness of copper

KC offers laser drilling microvias in both copper clad and unclad laminates. While we do recommend that outer layer foils be kept to half ounce or thinner for process efficiency, we are capable of handling much thicker copper cladding if your design calls for them.

To Sum Up

As long as aspects such as the above are taken care of, laser drilling is indeed the best choice in creating microvias. With the increase of miniaturization as well as high density of wiring and components, the use of laser-drilled microvias is only slated to increase.